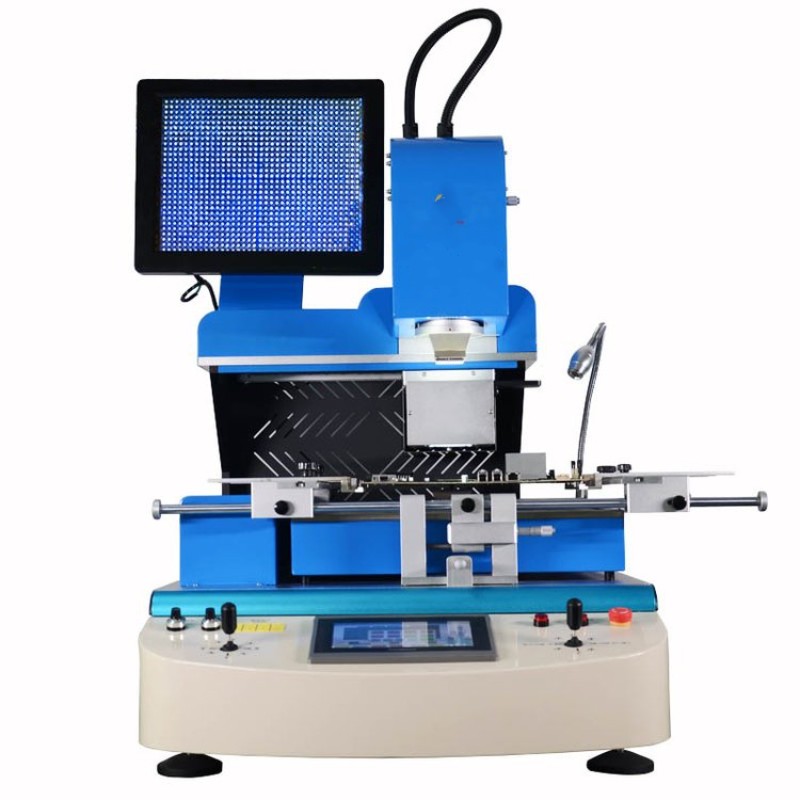

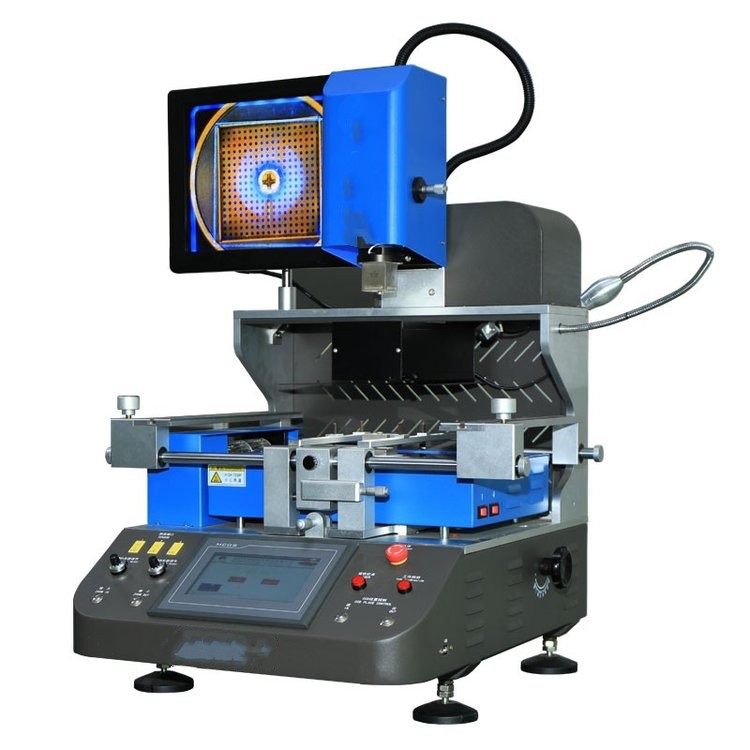

BGA Rework Station

Category SMT Peripheral

Tag BGA Rework Station

BGA Rework Station is a professional equipment used for repairing, disassembling, and soldering BGA packaging (Ball Grid Array Packaging) integrated circuits (ICs).

Additional information

| Power Supply | 220V 7600W |

|---|---|

| Component Zoom Range | 2~50X |

| Min IC Pitch | 0.15mm |

| Weight | 90KG |

Product Details:

BGA packaging is a common surface mounting technique, with solder joints located at the bottom of the package, forming a regular ball grid array. The BGA repair bench can precisely control the heating, blowing, and welding processes, allowing operators to repair and replace BGA packaging without damaging the circuit board and other components. camera alignment system, three independent temperature control, more accurate.

- Can be connected with computer control, measure temperature curve, transmit temperature curve parameter;

- The first and second temperature zone heater using good heating material, can adjust hot air flow and temperature accurately, produce high temperature breeze. The third temperature zone use far-infrared heating plate to preheat;

- The first, second zone controlled by 9 segment temperature up (down)+9 segment constant temperature, can store 10 groups temperature curve.

- First and second zone start running temperature at the same time, first, second and third start running temperature up and down at the same time;

- The first and second temperature zone over-temperature protection design.

- The heater of first temperature zone can adjust front and back, up and down, convenient to operate.

- The second temperature zone can adjust up and down according to the appearance of PCB board and height of components, prevent collision with PCB board;

- After remove and soldering, using high flow constant fan to cool the PCB board, prevent deformation of PCB board to ensure welding effect.

- Adjustable PCB jaw, prevent collision with components;

- Equipped with various size of hot air nozzle, can make according to customers requirement, hot air nozzle can 360 degree rotation, easy to replace.

- Adjustable high temperature resistance PCB bracket, positioning rack used anti-hot protection design;

- Upper heater with over-temperature protection;

- After finish remove and welding BGA, have sound alarm function;

- Handheld vacuum pen, convenient reliable and durable.

SPECIFICATION

| PCB Size | ≤L500×W400mm |

| PCB Thickness | 0.5~8mm |

| Workstation fine-tuning | Front/back)±7mm Right/Left±7mm |

| Fine-tuning accuracy | 0.01mm |

| Angle fine-tuning | 360° |

| Temperature Control | K Thermocouple PID Closed loop |

| PCB Positioning | Outer |

| Bottom preheat | Infrared 3000W |

| Main (Top+bottom) heater | Hot air 800W+800W |

| Power supply | Single phase 220V,50/60Hz,4.6KVA |

| Dimension | L670×W580×H600mm |

| Weight | Approx. 90kgs |